Stereolithography (SLA)

It is a Rapid Prototyping process for producing models, prototypes, patterns, and in some cases production parts using 3D CAD data.

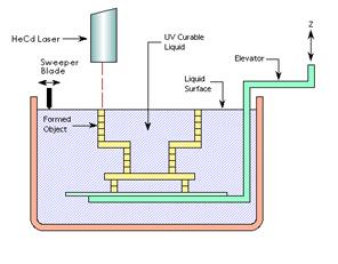

In this technique three-dimensional models are built from liquid a photosensitive polymer (epoxy resin/acrylic resin) that solidifies when exposed to ultraviolet light. As shown in the following fig, the model is built upon a platform which is situated just below the surface in a vat of liquid epoxy or acrylic resin. A low-power highly focused ultraviolet laser traces out the first layer, solidifying the object’s cross section while leaving excess areas liquid. After, an elevator incrementally lowers the platform in to the liquid polymer. A sweeper re-coats the solidified layer with liquid, and the laser traces the second layer atop the first. This process repeats until the prototype is complete. Afterwards, the solid part is removed from the vat and rinsed clean of excess liquid. Supports are removed and the model is then placed in an oven for complete curing.

Advantages

- SLA process can build complicated parts which cannot be possible by conventional

manufacturing process - High quality surface finish can be achieved

- Clear model with good resolution can be achieved

Applications

- Produce parts with very fine features and high quality visualisation models

- Fit and functional parts for assembly

- Models are used to flow visualisation and stress analysis

- Manufacturing medical models

- Master patterns for tooling and vacuum casting processes.

Limitations

- Higher Cost

- Material is limited to photosensitive polymer resin and it is fragile compared with other engineering plastic material.